BMW uses blockchain to increase resource transparency

BMW has initiated the organisation PartChain that uses blockchain technology to increase transparency in worldwide supply chains regarding raw materials and components. Interested companies are invited to join the initiative.

The aim of the project is to enable the seamless traceability of all components at the push of a button. The German company is using a combination of blockchain and cloud technologies to create transparency in complex supply chains. Blockchain is at the heart of the project because this technology guarantees the forgery-proof exchange of data. BMW says that the method has already proven itself in a test run: “In 2019, we successfully conducted a pilot project for the purchase of front lights. This year we want to extend the project to numerous other suppliers,” said Andreas Wendt, member of the Board of Management of BMW AG responsible for Purchasing and Supplier Network.

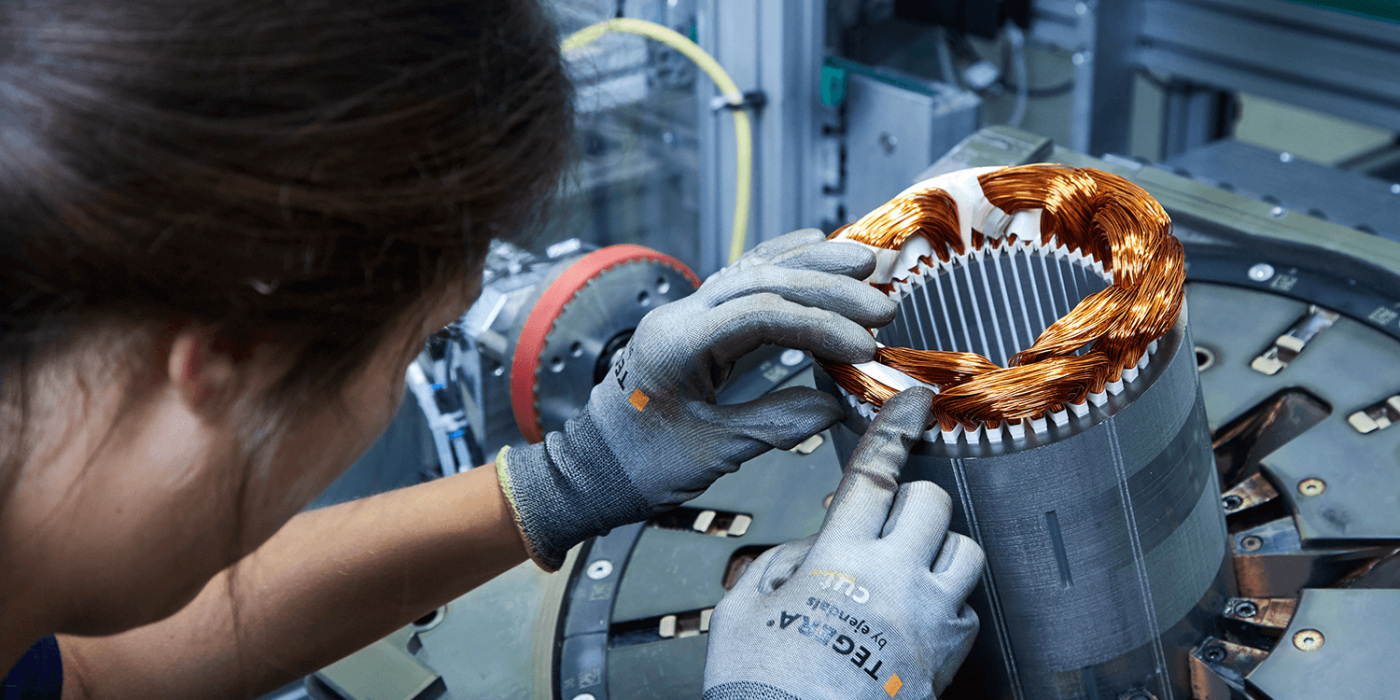

Transparency is particularly important in the use of such important finite resources, most obviously in the use of batteries. This is where BMW has been working towards more transparency in the extraction of raw materials. During the opening of the Munich battery competence centre, BMW boss Oliver Zipse reiterated that the goal was to achieve “complete transparency” in this regard. In October last year, the German company announced it was changing its resource strategy and would do without cobalt from the Congo for the incoming fifth generation of its electric car batteries. The company sources its cobalt from mines in Morocco and Australia before making it available to its own cell suppliers. In a few years’ time, however, BMW also plans to buy in the Central African country again. “We don’t want to exclude the Congo; it is our declared goal to source in the Congo again,” says material purchaser Peter Zisch. “We believe that we can do this again from targeted mines from 2025 onwards.” BMW is already supporting corresponding projects in Congo with BASF and Samsung SDI to establish clean and transparent cobalt extraction there.

BMW is not alone with the idea of a blockchain for supply chain transparency. Volvo and Volkswagen have also already presented their own projects to enable them to trace the sources of their cobalt precisely with the help of the blockchain.

With the Blockchain initiative, BMW wants to take all of its purchasing to the next level of digitalization. According to the Munich-based company, the use of blockchain is conceivable along the “entire automotive value chain”. Until now, the multi-level international supply chains have been difficult to understand in view of the large number of players and rapid changes. “Our vision is an open platform by means of which data within supply chains can be exchanged and shared securely and anonymously across industries,” says Wendt. With the idea of an open platform, other companies are explicitly invited to join the initiative. “An industry-wide solution would enable all partners involved to more closely link and coordinate their business processes across company boundaries,” says BMW, looking ahead.

Last year’s pilot project involved the BMW plants in Dingolfing and Spartanburg in the USA and, on the supplier side, three automotive lighting businesses. While these parties were purely concerned with tracking parts, in the long term BMW also expects the blockchain technology to enable the complete traceability of critical raw materials, “from the mine to the smelter”. In the newly-formed PartChain project, another ten or so suppliers will soon be integrated.

Meanwhile, BMW is already thinking further ahead with regard to the potential of an open blockchain platform. In order to create common standards and control models on which such a platform would have to be based, BMW has already co-founded the Mobility Open Blockchain Initiative (MOBI) in 2018. This is a cross-industry initiative made up of 120 automotive, mobility and technology companies that want to help block-chain technology achieve a breakthrough in the mobility sector. Within MOBI, BMW heads a working group for supply chain issues.

With reporting by Cora Werwitzke

0 Comments